|

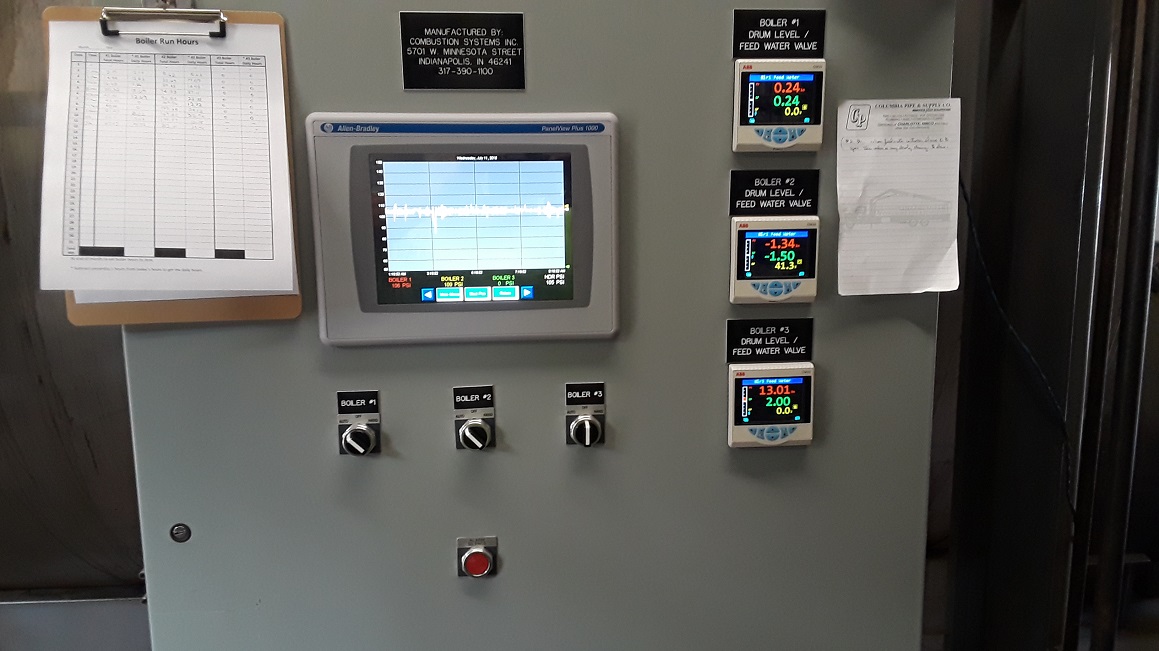

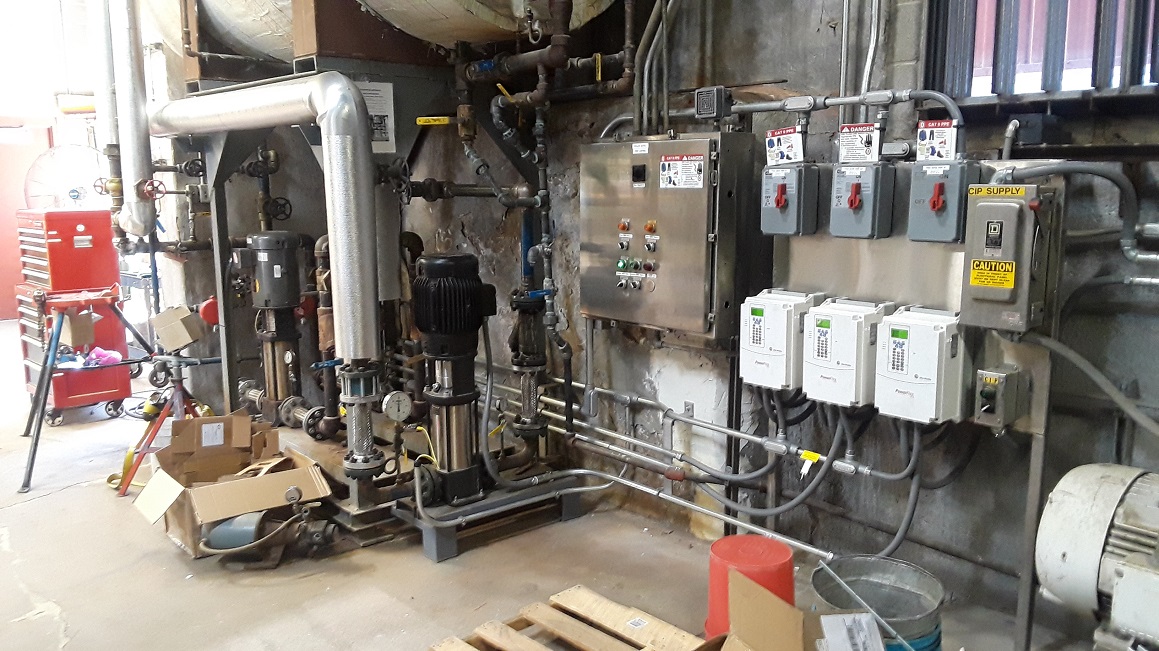

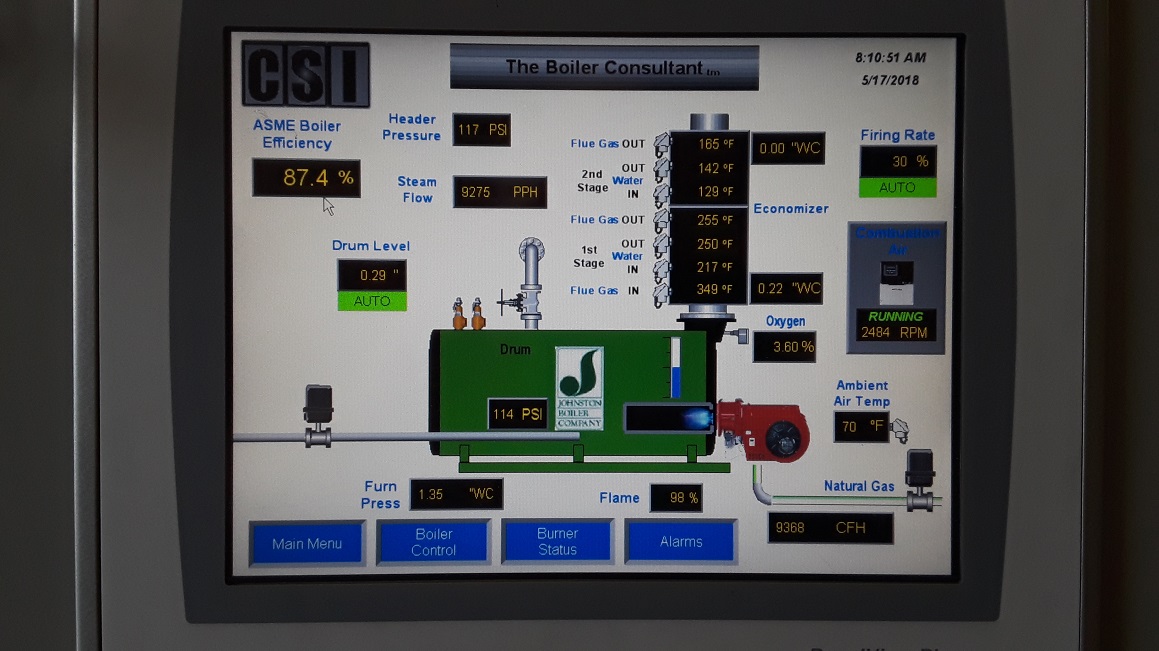

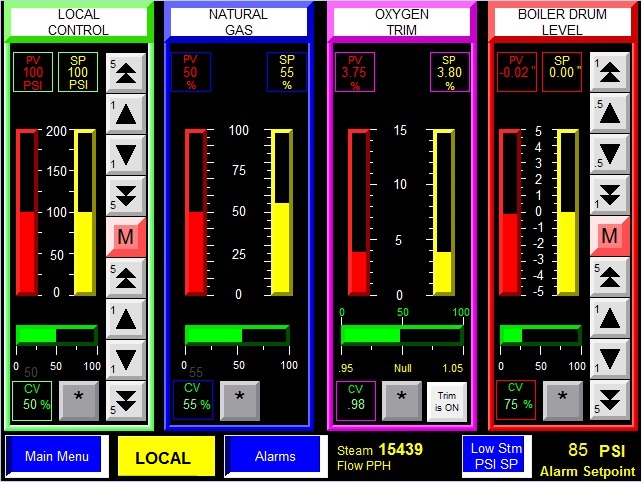

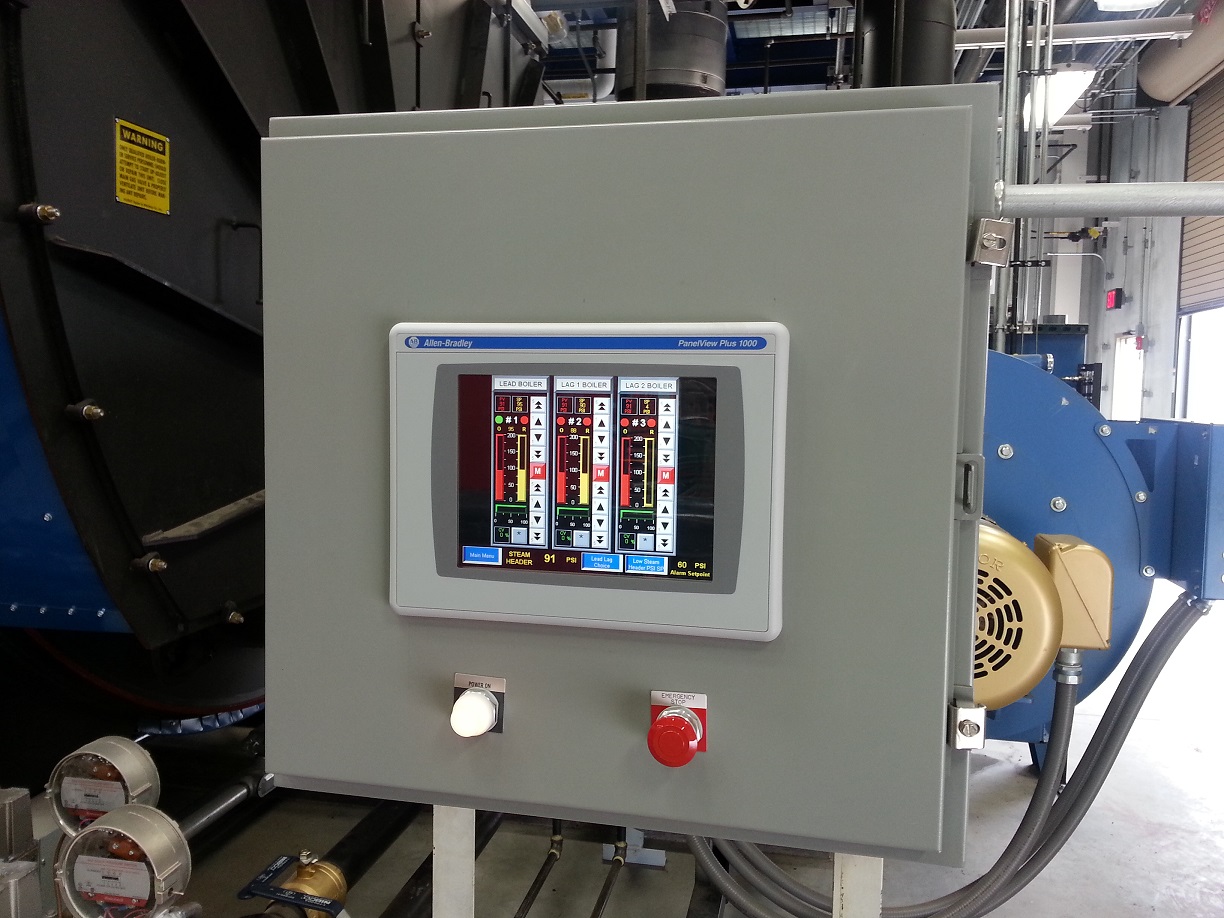

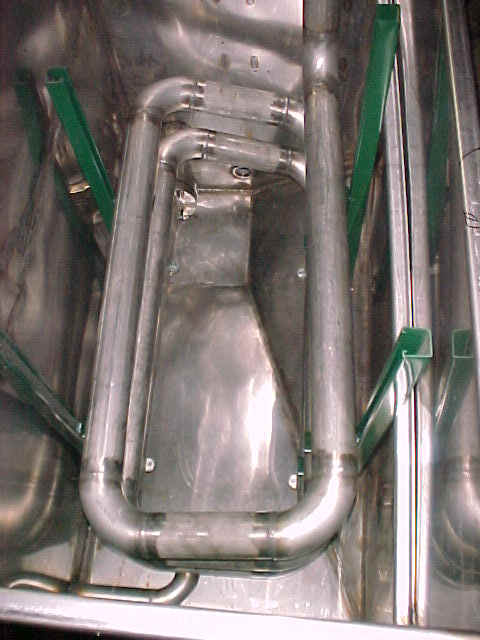

CSI sold a Johnston boiler with a Weishaupt burner to an out-of-state brewery. The boiler replaced one of their existing boilers. We also provided (3) new Grundfos feedwater pumps with Allen-Bradley VFD's. We designed an Allen-Bradley based PLC & HMI system to control a (3) boiler lead-lag system based on plant steam pressure and a (3) pump feedwater lead-lag system based on pressure. The PLC system also controls (4) chemical feed pumps. |

||